Discover The Role of Antifoaming Agents

3D Resources foam can be a common nuisance in various industries and processes, leading to reduced efficiency and potential equipment damage . To combat this issue, the use of antifoaming agents has become crucial. This article aims to provide Malaysians in Selangor with a comprehensive understanding of antifoaming agents, including their definition, functioning, and advantages.

What Are Antifoaming Agents?

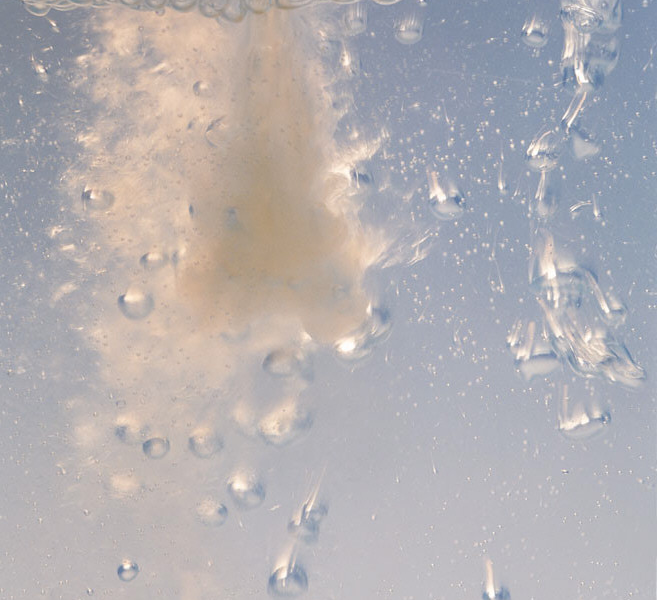

Antifoaming agents, also known as defoamers, are chemicals designed to suppress foam formation. They are widely used in industrial processes and applications where foam can hinder productivity. These agents work by reducing the surface tension of the liquid, destabilizing foam bubbles, and allowing trapped gases to escape.

How Do Antifoaming Agents Work?

Antifoaming agents consist of surface-active substances, typically silicone-based or non-silicone-based compounds. When added to a foaming system, they quickly spread over the liquid’s surface, breaking down the foam bubbles and preventing further foam generation. The agents either destabilize the foam’s structure or inhibit bubble formation, depending on the specific mechanism of action.

The Advantages of Using Antifoaming Agents

Enhanced Efficiency: Antifoaming agents improve process efficiency by minimizing foam-related disruptions. Whether in manufacturing, wastewater treatment, food processing, or pharmaceutical production, reduced foam formation allows for smoother operations and higher productivity.

Equipment Protection: Foam can accumulate and damage equipment, leading to costly repairs and maintenance. By incorporating antifoaming agents, businesses can protect their machinery and ensure its longevity, reducing downtime and operational expenses.

Improved Product Quality: In certain industries like food and beverages, excessive foam can negatively impact product quality. Antifoaming agents maintain product consistency by eliminating foam, resulting in better texture, taste, and appearance.

Waste Reduction: Foam formation often results in increased waste, especially in chemical processes and wastewater treatment. Antifoaming agents reduce the volume of foam, minimizing waste generation and promoting environmental sustainability.

Cost Savings: By preventing foam-related issues, businesses can save money in the long run. Antifoaming agents reduce the need for additional cleaning agents, equipment repairs, and product rework, resulting in cost savings and improved overall profitability.

Where to Find Reliable Antifoaming Agents in Selangor

Finding high-quality antifoaming agents in Selangor is crucial to ensure optimal performance and compatibility with specific applications. Local chemical suppliers and distributors specializing in industrial chemicals are excellent resources for acquiring reliable antifoaming agents. Additionally, online platforms and industry-specific trade shows can provide valuable information and connections to reputable suppliers.

Conclusion:

Foam can be a significant challenge in various industries, hindering efficiency, damaging equipment, and affecting product quality. Antifoaming agents offer an effective solution to combat foam-related issues.

By understanding the role and advantages of antifoaming agents, businesses and industries in Selangor can make informed decisions and select the right products to enhance their operations. Incorporating reliable antifoaming agents ensures smoother processes, increased productivity, and cost savings, leading to improved overall performance and competitiveness.